Generally speaking, tear resistant belt conveys large sized lumps and are very critical in most cases.

In fact, in every conveyor installation there are certain applications. For example, where the normal expected belt life significantly deteriorates due to continuous abuse resulting in premature failure caused by rip, tear and carcass fracture. Especially, in heavy duty mining applications, failures are catastrophic. As a result, it imposes heavy financial losses due to stoppage of production and downtime.

So for such applications demanding the highest impact, rip and tear resistance, Unique recommends our tear resistant belt. Because the special construction of the belt and the special cushion and cover rubber will ensure superior impact resistance and higher longitudinal flexibility of the belt. Thus guaranteeing a very low elongation at working load compared to conventional EP/NN fabric belts.

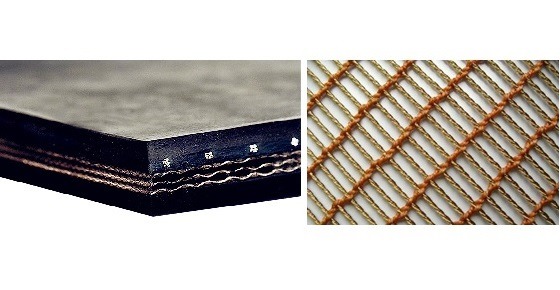

Structure:

- On both side or one side, the transverse reinforcement (steel cord, steel wire cord, fiber cord or textile fabric) is laid out

- Belt body comprises of the reinforcement covered with a layer of rubber

- Transverse Reinforcement Type Conveyor Belt consist of a left and right twisting wire, arranged evenly and longitudinally in the belt

Features of Our Transverse Reinforcement Type Conveyor Belt:

- Good impact resistance

- An excellent property of reducing tear by external force

- Long belt life

- Rip resistance

- Cord protection

Product Application:

Therefore, the anti tear conveyor belt is ideally suited for the following applications:

1. Heavy impact applications e.g. primary crushers

2. Material fall height exceeding 2 m (6.5′)

3. Lump size more than 250 mm

4. Long haul applications

5. Conveyors susceptible to presence of tramp material

6. Scrap recycling plants, log decks.

Tear Resistance Testing

In addition, tests for rip and tear resistance are only made on the actual belt carcass. So the top and bottom covers are always removed. As a result, this ensures that the thickness and quality of the cover do not influence the accuracy and consistency of the tests.