Sidewall Conveyor Belt Without Cleats? Find Our Feeder Conveyor Belt HERE

Sidewall Conveyor Belt Application:

In some conditions, due to the limit space or in case of lifting material at a large slope, Corrugated Sidewall Conveyor Belt is always used to avoid material spilling. This system can convey materials vertically and also can work at a large slope from 0 degree to 90 degree and allow heavy load material conveying.

Corrugated sidewall conveyor belt is one of the most effective ways of elevating materials. It is mainly used for materials handling at harbor terminal (rock/ ore/ coal), chemical industry (fertilizer), power plants (coal/ ash/ gypsum), crushing plants (rock, gravel/ sand), mining (ore/ limestone/ chemicals), steel plants (alloys/ scrap metal/ iron ore), etc.

These technically advanced sidewall conveyor belt ensure fast and safe movement of powdery and lumpy material even in bulk quantity.

Features:

- Low maintenance cost and long belt life

- No spillage with steep angle conveying

- Maximum utilization of space

- No spillage with steep angle conveying

- Low power requirement

- Allows material conveying at 0°- 90°

Construction:

Base belt: Multi-ply (EP/NN/CC) fabric type or Steel Cord type

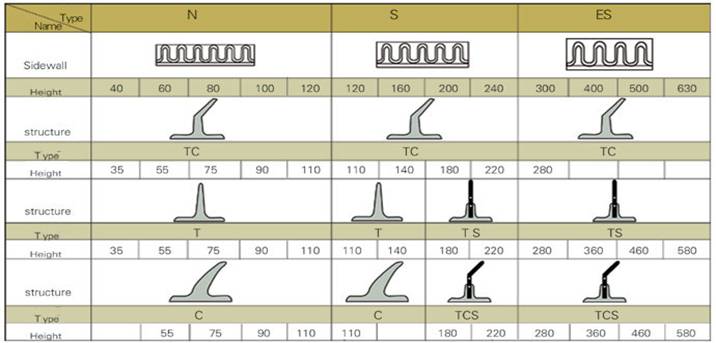

Sidewall: N, S, and ES type

Cleat: T, C, TC, TS and TCS type

Transverse reinforcement: According to clients’ requirement

Technical Data:

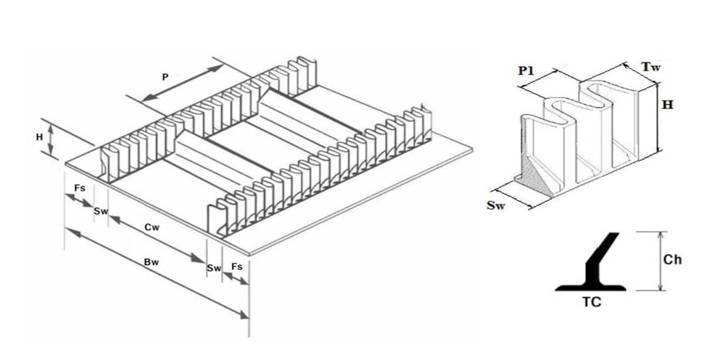

| Base Belt Width (mm) | Sidewall Height (mm) | Cleat Height (mm) | Width of Base Sidewall (mm) | Length of Cleat (mm) | Insert (mm) |

| Bw | H | Ch | Sw | Cw | Fs |

| 400 | 60 | 55 | 50 | 180 | 60 |

| 80 | 75 | ||||

| 100 | 90 | ||||

| 500 | 80 | 75 | 50 | 250 | 75 |

| 100 | 90 | ||||

| 120 | 110 | ||||

| 650 | 100 | 90 | 50 | 350 | 100 |

| 120 | 110 | ||||

| 160 | 140 | 75 | 300 | ||

| 800 | 120 | 110 | 50 | 460 | 120 |

| 160 | 140 | 75 | 410 | ||

| 200 | 180 | ||||

| 1000 | 160 | 140 | 75 | 550 | 150 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 1200 | 160 | 140 | 75 | 690 | 180 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 300 | 280 | 105 | 630 | ||

| 1400 | 200 | 180 | 75 | 830 | 210 |

| 240 | 220 | ||||

| 300 | 280 | 105 | 770 | ||

| 400 | 360 | ||||

| 1600 | 200 | 180 | 75 | 970 | 240 |

| 240 | 220 | ||||

| 300 | 280 | 105 | 910 | ||

| 400 | 360 | ||||

| 1800 | 240 | 220 | 75 | 1110 | 270 |

| 300 | 280 | 105 | 1050 | ||

| 400 | 360 | ||||

| 500 | 460 | 125 | 1010 |