EP Conveyor Belt

EP conveyor belt can suit a wide range of applications for bulk material handling. And the cover rubber grades are specially designed with enhanced cut, gouge & wear properties. So these belts are normally for transporting crushed rock, limestone, coal, iron ore, sand, cement, wood chips, furnace slag, aggregate and so on. In general, we have been offering unique types of covers which excel in their respective application as below.

As a result of our persistent efforts, we have earned a reputable position in manufacturing, supplying and exporting conveyor belt. Moreover, the entire range of belts is popular in the global market. Because it has smooth functioning and superior quality. These belts are suitable to convey medium to heavy loads from one place to another. Before shipment, all products are duly checked on several quality parameters. So that our clients can avail only flawless belts. Also it is made available in various specifications. In order to meet the demands of our clients in the best possible way.

EP Conveyor Belt Features

We offer wide range of EP conveyor belt suitable for conveying normal temperature material. Without any doubt, it can resist maximum up to 60 degree. As a matter of fact, our product is constructed with fabric (carcass) and rubber compound. While rubber cover is compounded from the best quality natural rubber. And this provides superior resistance to cutting and gouging. Thus to load support and convey different type and size of material, either short to long distance or light to heavy load transportation of materials.

EP Conveyor Belt Application:

Our belt is mainly used in all the process industries to carry different materials, for example:

1. Fertilizer Plants – Super phosphate in lump and powder

2. Cement Plants – limestone, Clay slacked lime, sand, Cold clinker

3. Steel & Power Plant -Coal, Coke, ashes and crushed metallic ores

4. Stone Crushing Industries – Granite & Blue metal, crushed stone

5. Biomass Power Plant – biomass fuels, wood chips, paper bales, gravel, sized coke

6. Glass Industries – timber crushed glass, granite, all types of slacks, sand stones, chipping, quartz, and re-claimers.

EP Conveyor Belt Product Characteristics:

Common Widths : from 500 mm to 2600 mm (20” to 102”)

Carcass Variety Available : either EP or NN

Common Belt Rating : from 200 to 3150 kN/m (110 to 1800 PIW)

No. of Plies : from 2 ply to 7 ply

Rubber Cover Compounds : Refer table for detailed properties

Rubber Cover Thickness : from 1.5 mm to 25 mm (1/16” to 1”)

Edge : Cut/Moulded Edge

Splicing Method : Hot/ Cold/ Mechanics

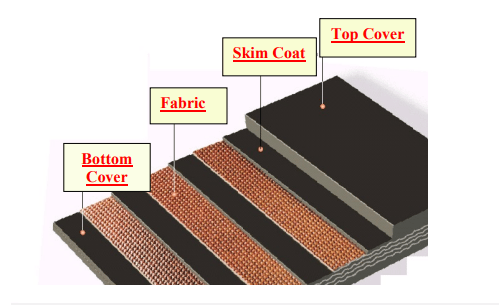

EP CONVEYOR BELT CONSTRUCTION

Bottom Cover – Excellent both in abrasion and flexibility, furthermore provides surface friction to pulleys & idlers

Carcass/fabric – Extremely low stretch characteristic of fabric with good troughability

Skim/coating – Compounded for excellent adhesion between plies for protecting against ply separation

Top cover – Particularly design to protect the carcass from service conditions just like oil, heat, abrasion etc.

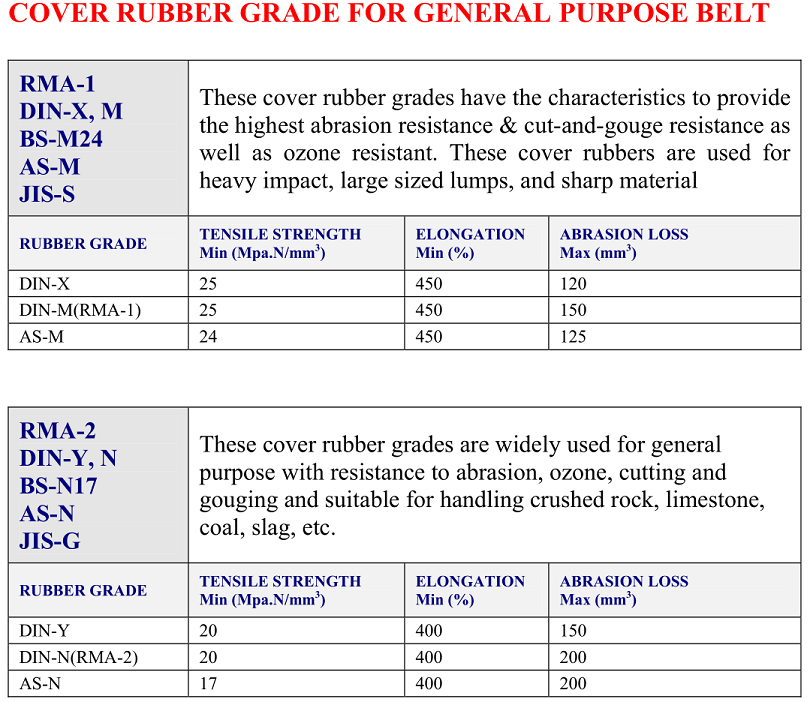

COVER RUBBER GRADE

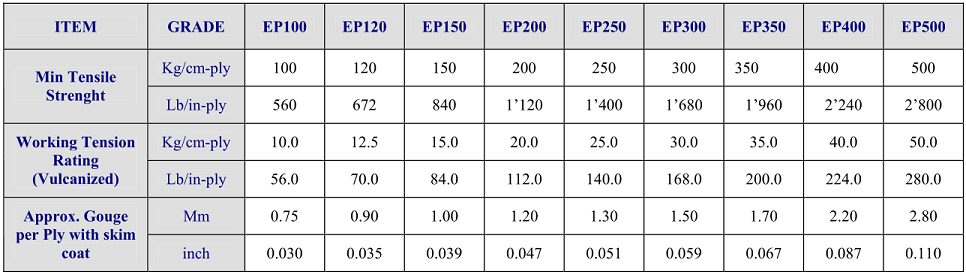

BELT RATING

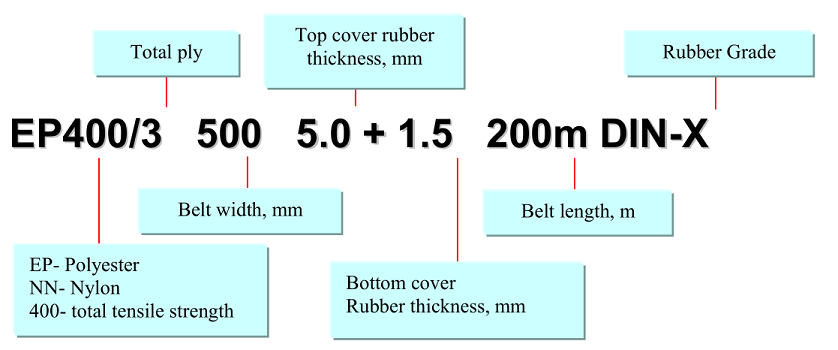

DESIGNATION OF EP CONVEYOR BELT

EP: Basic strength material is EP fabric

630/4: Tensile strength in warp is 630N/mm, as a result of 4 plies EP fabric

1200: belt width is 1200mm

6+2: Thickness of top and bottom cover rubber 6mm,2mm

AS M: Cover rubber grade(According to AS-M)

Generally speaking, based on rubber cover, conveyor belts can also be categorized as below:

In conclusion, this type of conveyor belt is suitable for transporting lump, granular, powdery materials of normal temperature, and non-corrosion. Besides General-used EP conveyor belt, there are some other types as well. For example, fire resistant type, heat-resistant type, oil resistant type and so on.

Our belt is of superior quality and reliable performance so it could be economical substitute for some famous brands such as Dunlop, Contitech, Bridgestone, SIG, and so on.