Unique Conveyor Belting offers a wide range of rubber conveyor belts. On the whole, all our belts are designed with the aim of reaching maximum lifespan. All unique rubber conveyor belts fulfill international standards in order to meet your specific requirements. What’s more, our rubber conveyor belt can be cost effective replacement product for some brands like Bridgestone, Dunlop, Continental, Phoenix, etc.. Accordingly, it saves your cost.

Classification Of Rubber Conveyor Belt

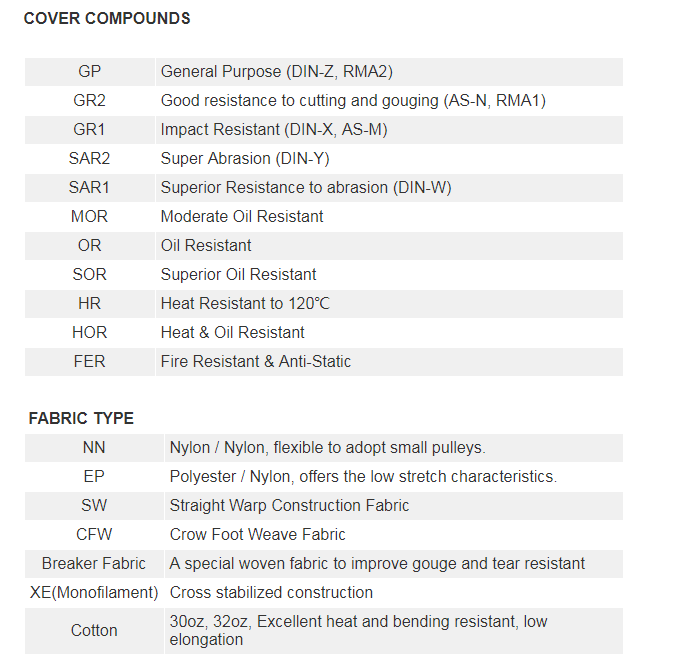

Rubber Cover Grade

Carcass Improvements

Belt Profiles

OIL RESISTANT CONVEYOR BELT

CHEMICAL RESISTANT CONVEYOR BELT

COLD RESISTANT CONVEYOR BELT

Generally, the basic design of the rubber conveyor belt consists of different types of cover rubber and carcass – reinforced fabric.

1. Cover rubber. The conveyor belt’s top layer usually compose of either natural or synthetic rubber. It is cover rubber which protects the carcass. Especially, it has abrasion, temperature, petroleum, chemical, static and fire-resistant characteristics. For this reason, you should choose the right cover grade depending on the working conditions.

2. Carcass. Maintains the tension of the rubber conveyor belts and supports the transported products. The carcass of the rubber conveyor belt usually compose excellent bonded rubber using coated cloth, nylon, polyester, steel wire or aramid. Steel Cord, NN (Nylon-Nylon), EP (Poliester-Nylon), SW (Straight Warp), Aramid fibers or other materials

3. Adhesive Rubber. Maintains the adhesive power between all layers of carcass and the cover rubber. As a result, it keeps their durable flexibility and tension.

4. Reinforced cover. It is for protecting the carcass. Particularly this is in case that the products are larger or a tear occurs. Because significantly shaken in worse working conditions than specified will put excess load on the top cover and carcass.

In order to offer the finest rubber conveyor belt appropriate for these sectors and to meet clients, we offer different rubber conveyor belts. Without any doubt, these belts can vary by type of carcass, fabric inserts, cover rubber, implementation and design.

As haves been stated, we can fabricate these rubber conveyor belts in varied grades and sizes. And this make sure our belts will perfectly meet the specific demands of our clients. In fact, our range of rubber conveyor belts are popular and reliable in the industries for saving in labor cost and time.

We dispose of a wide product line with rubber conveyor belts. What’s more, we can manufacture in several constructions. Either open, endless or other confection possibilities.

Rubber Conveyor Applications:

In general, our rubber conveyor belts are widely used in mining and other industries. For example, coal, steel, non-ferrous metal plants, thermal power plants, cement plants, food processing, and several industrial and agricultural applications, etc..