Heat resistant conveyor belt is well-suited for heat resistance applications. For example somewhere the temperature of conveyed materials is over 80°C. In general, heat resistant conveyor belt finds applications in the conveying of the following material:

Clinker | Sinter | Fly ash | Asphalt/Hot mix | Metcoke | Foundry sand | Burnt Lime

In fact, several manufacturing processes involve heat generation or conveyance of hot material. Usually end user may select belt on the basis of certain design criteria. However, due to process variables, the actual ambient conditions are much more than originally estimated.

Due to the severity of the operating environment, belts tend to fail for the reason of:

Cover hardening | Ply delamination | Belt deformation | Joint failure

Certainly, correct product selection is essential. Because it is in order to ensure the continued uptime of a conveyor and the belt.

Since we have vast experience in putting together a unique array of heat resistant belt, we are qualified to supply suitable belts for conveying your hot stuff.

Features

- Excellent both heat and abrasion resistant cover rubber compound

- Perfect to protect conveyor belt from cracking and hardening by heat

- Specially heat-treated and dipped fabric for reducing carcass shrinkage by heat ageing

- Rubber cover and carcass capable to withstand high temperature

Specifications:

Cover rubber: EPDM rubber or SBR rubber.

Carcass: polyester fabric

Furthermore, we can make endless belt in loop according to client’s request.

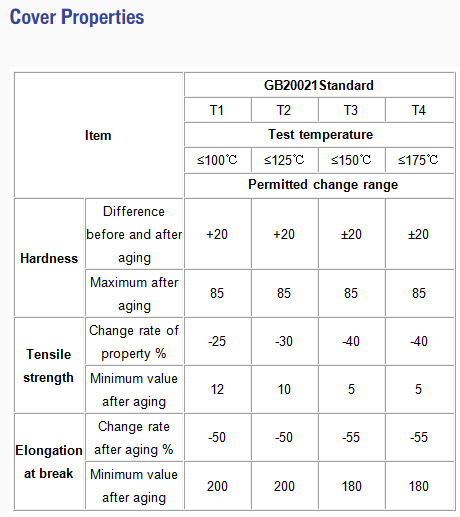

In summary, as per Chinese standard GB/T20021-2005 , We have four different types as below.

HRT1 Heat Resistant Grade Belts

HR(T1) – Firstly, HR (T1) Conveyor Belts are suitable to convey material in continuous temperature of 120 degree centigrade for coarse materials and 100 degree centigrade for fines. Maximum Intermittent Temperature upto 125 mainly used in Paper, Foundries, Chemical & Fertilizer plants etc.

SHRT2 Heat Resistant Grade Belts

SHR (T2) – Secondly, SHR (T2) Conveyor Belts are suitable to convey material up to 120 degree centigrade for fines and 150 degree centigrade for coarse material. Maximum Intermittent Temperature up to 150 ,These Conveyor belts are mainly for conveying Sintered ore, Pellet, Coke, and Clinker Etc.

UHRT3 Grade Heat Resistant Conveyor Belts

Thirdly, UHR(T3) Grade conveyor belts are used for high temperature applications. It is suitable to convey material in continuous temperature of 150 degree centigrade and a peak temperature of 180 degree centigrade. Maximum Intermittent temperature up to 180 These conveyor belts are mainly used to handle red hot materials such as Cement, Clinker, Sintered Ore and Phosphate.

Recommendations:

The service and performance life of heat resistance belt mainly depends on proper selection as per temperature of conveying material and construction of belt. But there is also other factors involving which can minimize the performance. For example, wear properties of the materials, the fall during loading, the size of the material, the length of the belt, the speed of the conveyor and any chemical action which may be involved. Higher thickness of the cover is also essential because the cover acts as a barrier between the heat source and the carcass.